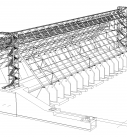

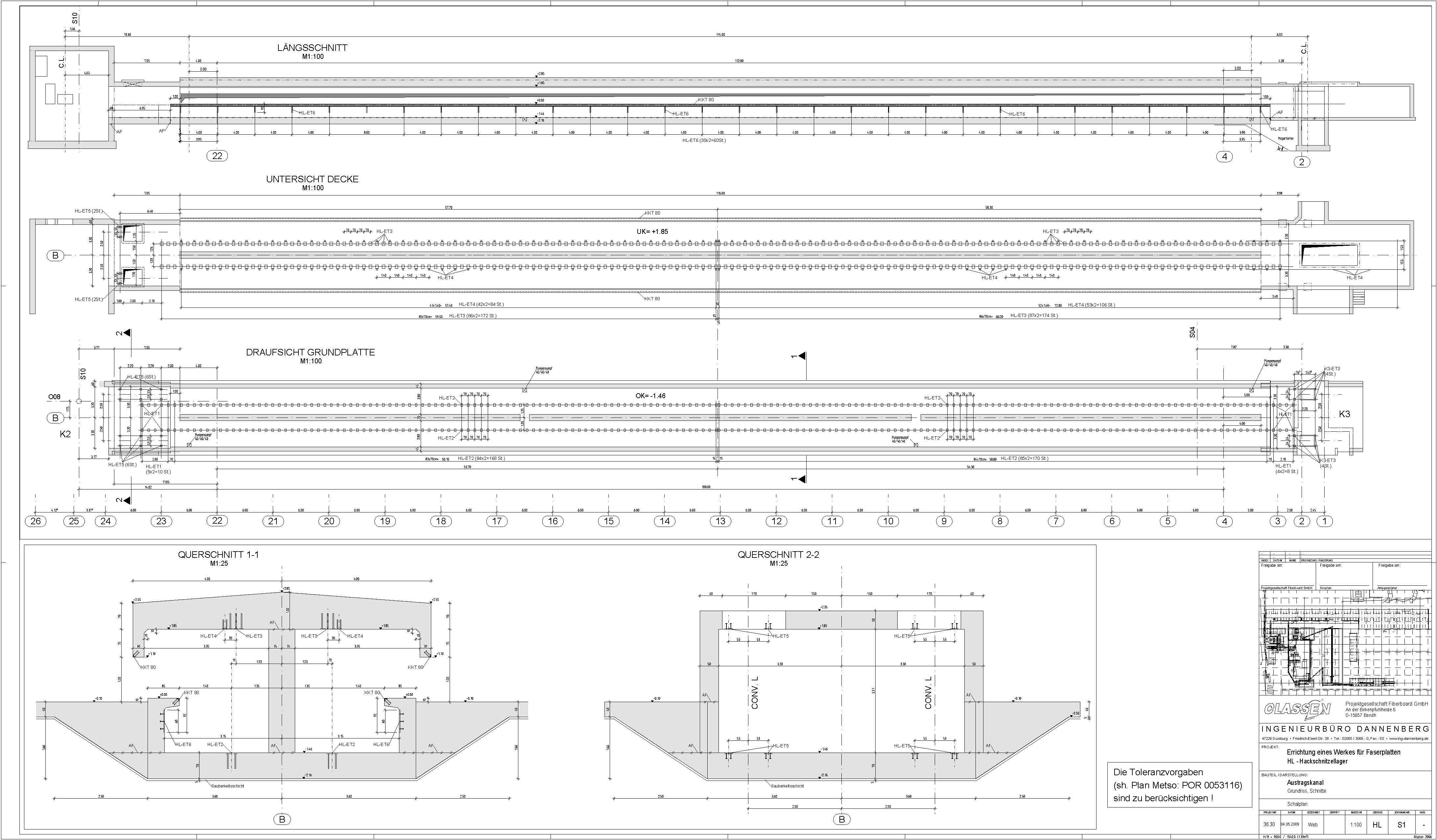

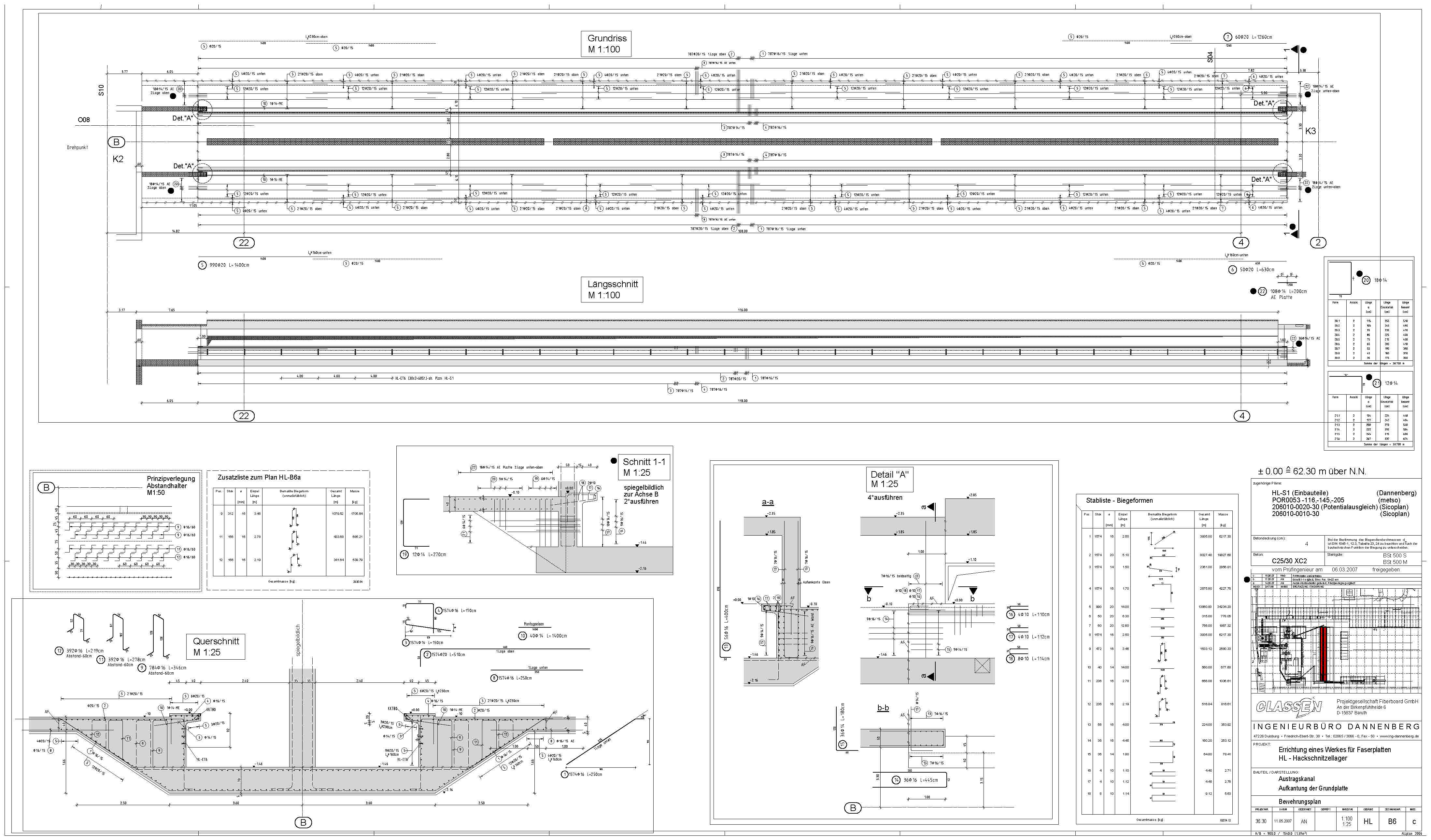

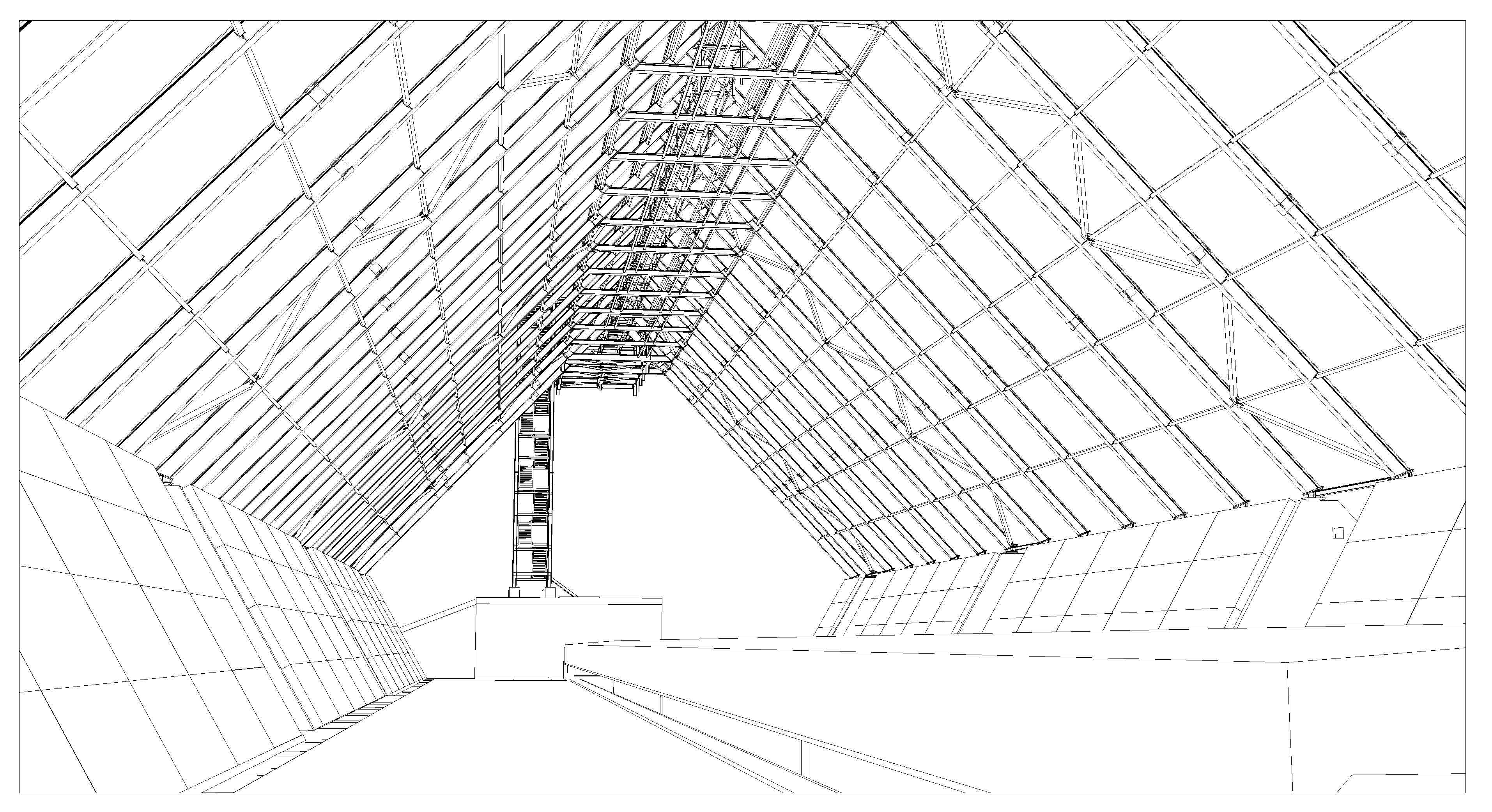

The about 120m long woodchip storage can carry a production volume of woodchips of three days. On a conveyor under the roof the woodchips are carried to a dump. Through discharge srew conveyors on top of the base plate the woodchips are pulled inside onto another conveyor in the discharge-canal. They are then transported to the glue and fiber preparation (LF) for further processing.

Special construction requirements:

• The woodchip storage is constructed to be able to close the roof to minimize wind drift.

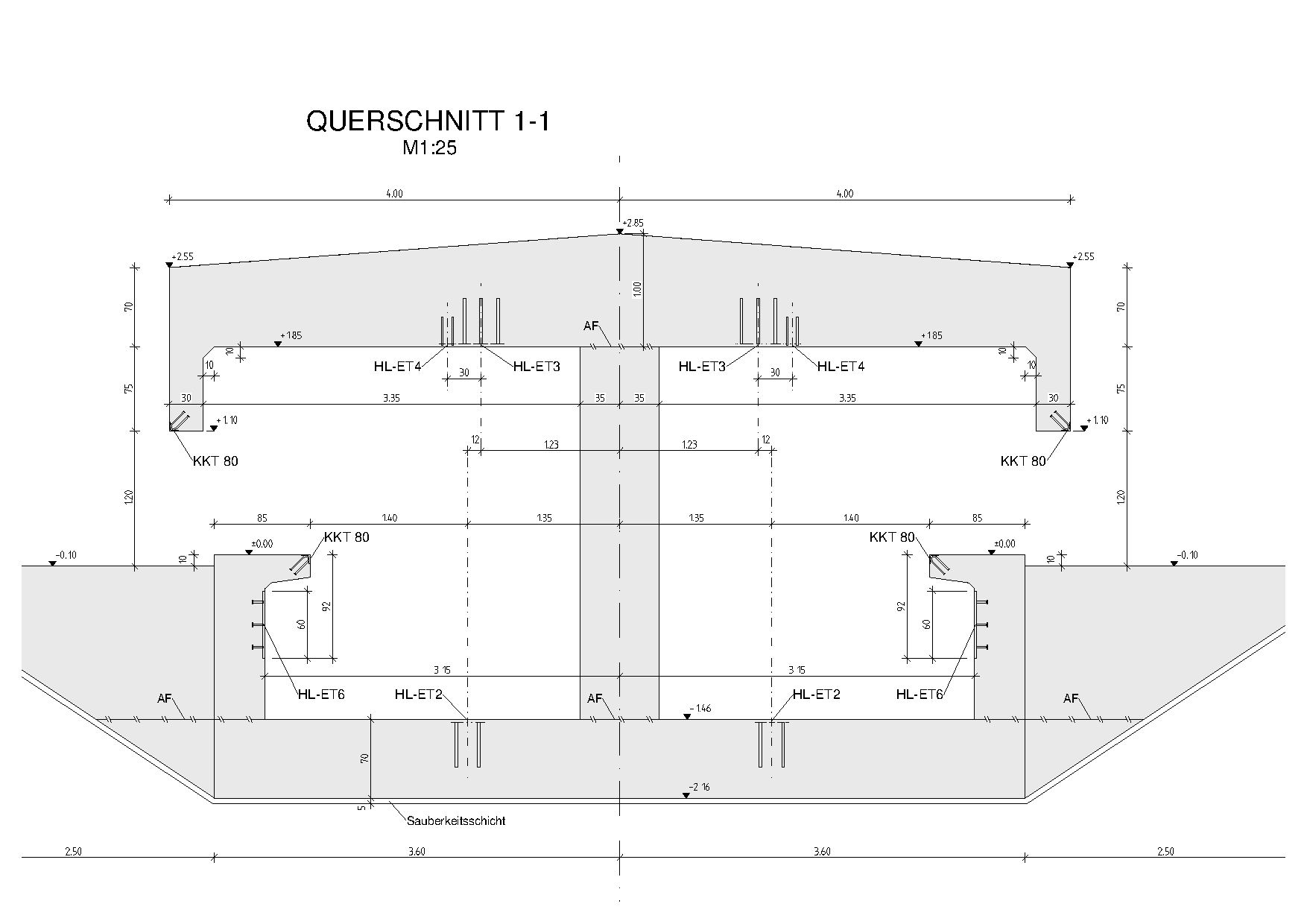

• The discharge devices are carried by a steel-concrete-mushroom-construction, that also has to carry the whole uneven woodchips bearing load.

Further Fiberboard Part Projects:

Framework for the dryer

Bark stripper and chopper